The Role of Aluminum Profiles in Energy Efficiency

Discover how aluminum profiles contribute to energy efficiency and how Kenan Metal is a pioneer in sustainable projects!

Today, energy efficiency has become a high on the agenda of both individuals and companies. Various solutions are being developed to increase energy efficiency in construction, automotive, aviation and many industrial sectors. One of these solutions is to use aluminum profiles. Aluminum stands out as a material that supports energy efficiency thanks to its lightness, durability, recyclability and potential to provide thermal insulation.

Energy efficiency has become one of the most important requirements of the modern world. Preferring energy efficient materials in buildings, vehicles and industrial structures provides a great advantage in terms of both sustainability and cost management. Aluminum profiles are one of the best options that increase energy efficiency with their lightweight, durable, recyclable and heat-insulating properties.

Kenan Metal contributes to the energy efficient structures of the future with the aluminum profiles it produces and takes important steps for a sustainable world. Kenan Metal continues to assume a pioneering role in the sector in order to take part in projects sensitive to energy saving and to offer high quality aluminum profiles to these projects.

The Importance of Aluminum Profiles in Energy Efficiency

Aluminum profiles play an important role in reducing the energy consumption of buildings. The light weight of aluminum allows building elements to be transported and assembled using less energy. In addition, aluminum's ability to provide thermal insulation minimizes heat losses and contributes to buildings consuming less energy.

Energy efficiency means the ability of a building or product to perform a specific task using the least amount of energy. In this context, thanks to the advantages provided by aluminum profiles, it helps to use energy more efficiently and reduce operating costs.

Read This: Sustainability and Recycling in Aluminum Profile Production

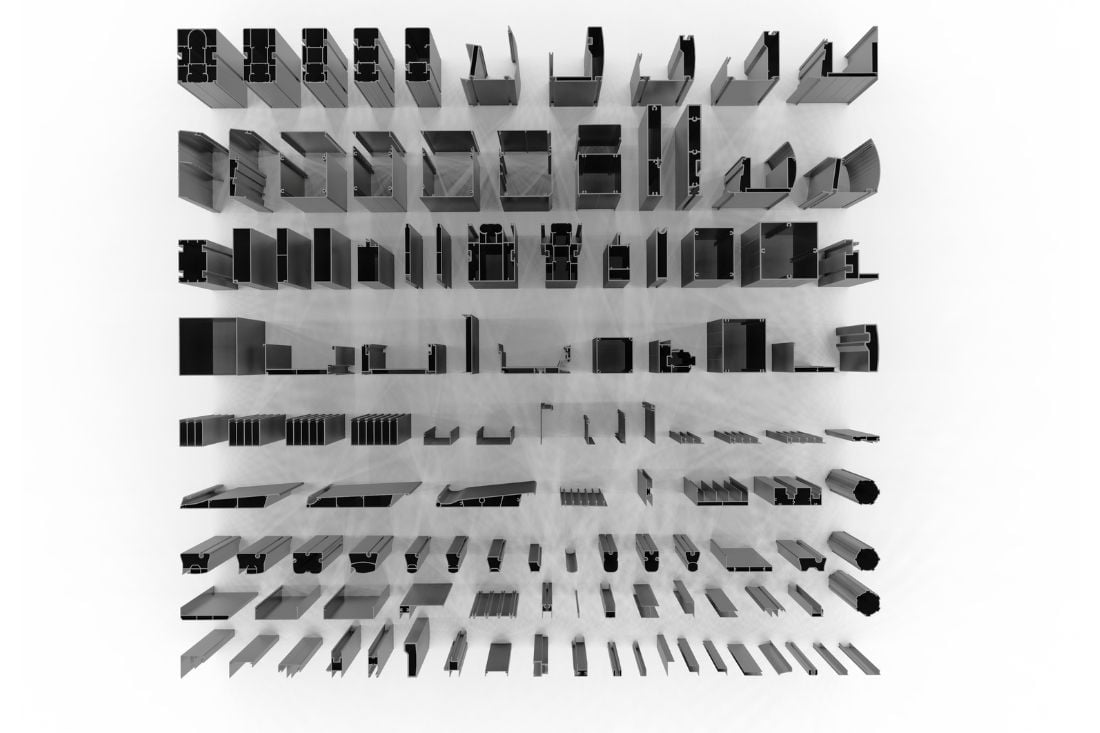

Features of Aluminum Profiles Contributing to Energy Efficiency

- Thermal Insulation: Aluminum profiles are produced with an insulation technology called thermal barrier. The thermal barrier is a layer created inside the aluminum profile using plastic or another heat insulating material. This layer prevents hot or cold air inside from escaping or hot or cold air outside from entering by preventing thermal bridging. Thus, window and door systems made with aluminum profiles minimize heat loss by reducing the energy consumption of the building.

- Lightness and Durability: Aluminum is a lighter material compared to steel, but it is also very durable. Thanks to these features, structures made using aluminum profiles both consume less energy and provide durability. Thanks to its light weight, aluminum profiles also require less energy to transport and install, which contributes to energy efficiency.

- Recyclability: Aluminum is a fully recyclable material. Recycled aluminum requires 95% less energy than the production of new aluminum. Therefore, as a sustainable material, aluminum profiles release less carbon into the environment. The recycling process of aluminum not only increases energy efficiency, but also provides a sustainable alternative in environmentally friendly projects.

- Long Life and Low Maintenance: Aluminum profiles are rust and corrosion resistant. Thanks to this durability, aluminum profiles maintain the durability of the structure for many years. This feature reduces the need for frequent repairs or replacements in buildings, reducing both costs and energy consumption. Long-lasting structures mean less resource consumption and less energy use.

Contribution of Aluminum Profiles to Energy Efficiency: Application Areas

Aluminum profiles are used in many sectors to increase energy efficiency. Here are some application areas where these profiles stand out:

- Building and Construction Industry: Aluminum profiles are frequently used in windows, doors, facade systems and sun shading systems to provide energy efficiency. Especially in buildings with large windows, aluminum profiles provide durability and reduce energy consumption by providing thermal insulation.

- Automotive Sector: Aluminum profiles contribute to less fuel consumption by reducing the weight of vehicles. This both increases fuel efficiency and reduces carbon emissions. Aluminum profiles are also used in electric vehicles to increase vehicle range and support energy efficiency.

- Aviation Industry: Making airplanes lightweight yet durable is essential to reduce energy consumption. The light weight of aluminum profiles increases energy efficiency by reducing fuel consumption of aircraft.

- Solar Energy Systems: Aluminum profiles are used in the frames of solar energy panels, increasing the durability of the panels and ensuring their longevity. This contributes to energy efficiency.

Building Energy Efficient Buildings with Aluminum Profiles

The use of aluminum profiles in projects targeting energy efficiency is becoming increasingly widespread. Leading companies in the sector, such as Kenan Metal, contribute to energy efficient buildings with the aluminum profiles they produce at high quality standards. Kenan Metal adds value to sustainable projects with the solutions it offers in a wide range from the construction sector to automotive.

Aluminum profiles produced by Kenan Metal play an important role in increasing the energy efficiency of projects with their thermal insulation properties, durability and recyclability. Kenan Metal's profiles provide both cost advantages and minimize energy consumption in environmentally sensitive and energy-saving buildings.