Billet Production

Kenan Metal

Billet Production

Kenan Metal produces high quality aluminum billets with its billet production facility, which is the leader in the sector. Equipped with modern and high-tech equipment, our facility is managed by specialized personnel and offers superior quality products to our customers.

Our production process starts with the use of carefully selected raw materials. Our advanced automation systems optimize the production stages, ensuring high efficiency and low error rates. The steels are heated in our specially designed furnaces and shaped by high-pressure casting machines. After this stage, our products are inspected by strict quality control processes and billets with consistent dimensions and excellent surface quality are offered to our customers.

-

Kenan Metal manufactures aluminum billets with renewed high-tech systems and produces products in accordance with project needs. High-quality and world-class billets offer advantages such as long-term use in extrusion molds, increasing efficiency and reducing costs.

-

Kenan Metal, which produces products in the aluminum sector with more than 30 years of experience, works with the principles of quality raw materials, efficient technology, skillful workmanship and precise control. With all this care, the production of billet is completed in-house from start to finish.

-

All products produced in the billet production line are tested with high-precision measuring systems. For manufactured aluminum billets, central cracks and capillary gap problems are controlled with an accuracy rate of 100%. The finished billets are delivered to the Extrusion Plant.

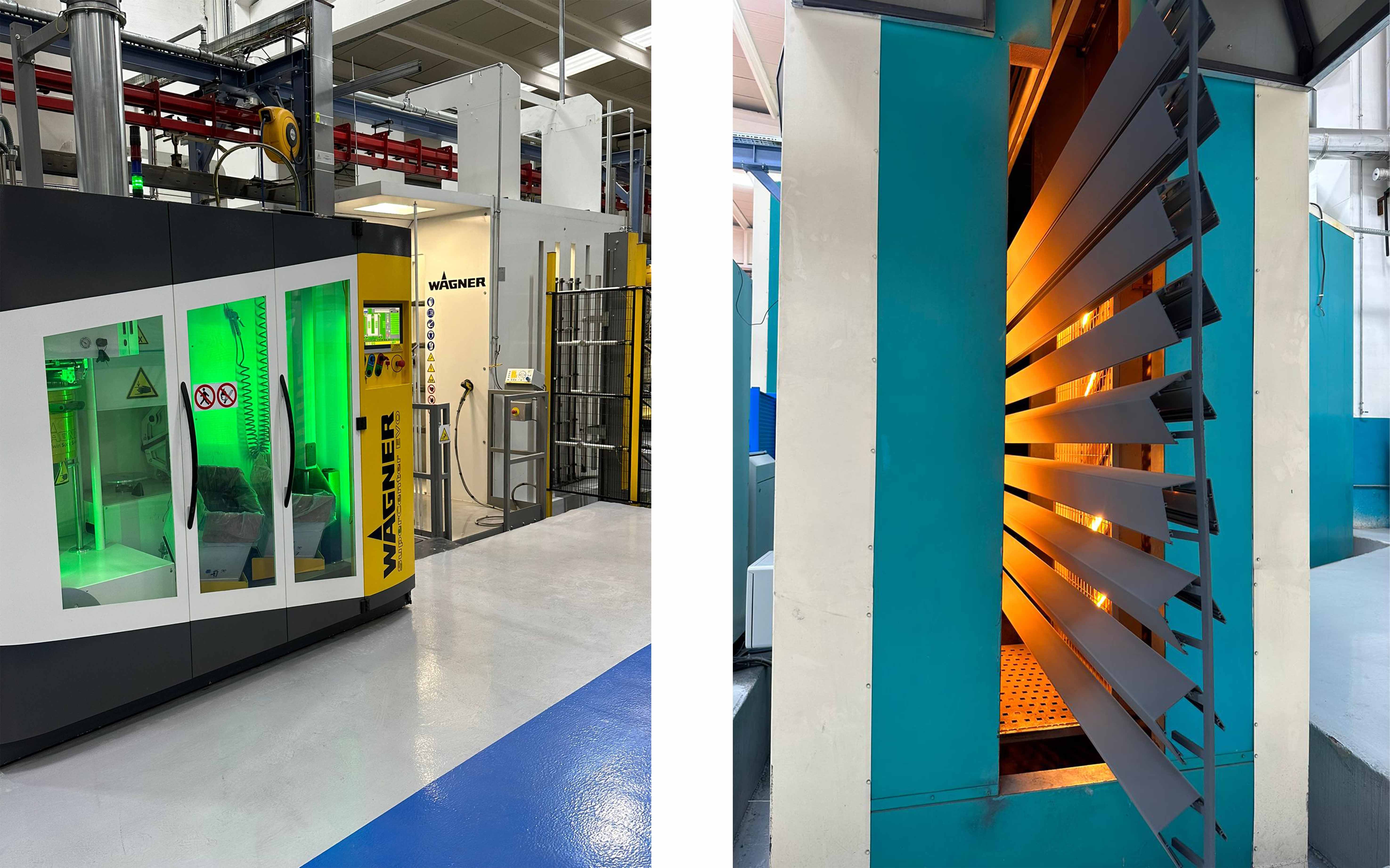

The molds used in profile production are manufactured with great care with very precise tolerances on high-tech CNC machine tools located on site in accordance with customer designs and needs.

Kenan Metal manufactures 1500 TONS (5 INCHES), 1800 TONS (7 INCHES), 2400 TONS (8 INCHES) and 4000 TONS (10 INCHES) with 4 extrusion press machines in a modern production facility designed and built specifically for the production of aluminum profiles. It has achieved an annual production capacity of 36,000 tons with its quality, which has been certified by TSE, IATF, ISO 9001, ISO 14001, ISO 10002 and OHSAS 18001.

Kenan Metal has a production capacity of 18,000 tons with a 12-meter electrostatic paint line. It carries out painting operations with a power and free z-type electrostatic paint booth with a capacity of 12,000 tons and a tunnel-type electrostatic paint line with a capacity of 7,200 tons.

Kenan Metal has a special anodizing coating line with a capacity of 6,000 tons. Anodizing of aluminum profiles in different colors and surface properties is carried out.