Surface Treatment of Aluminum Profiles: Anodizing and Painting Techniques

Anodizing (anodic oxidation) and painting techniques are widely used methods to protect the surfaces of aluminum profiles, increase their durability and provide aesthetic appearance.

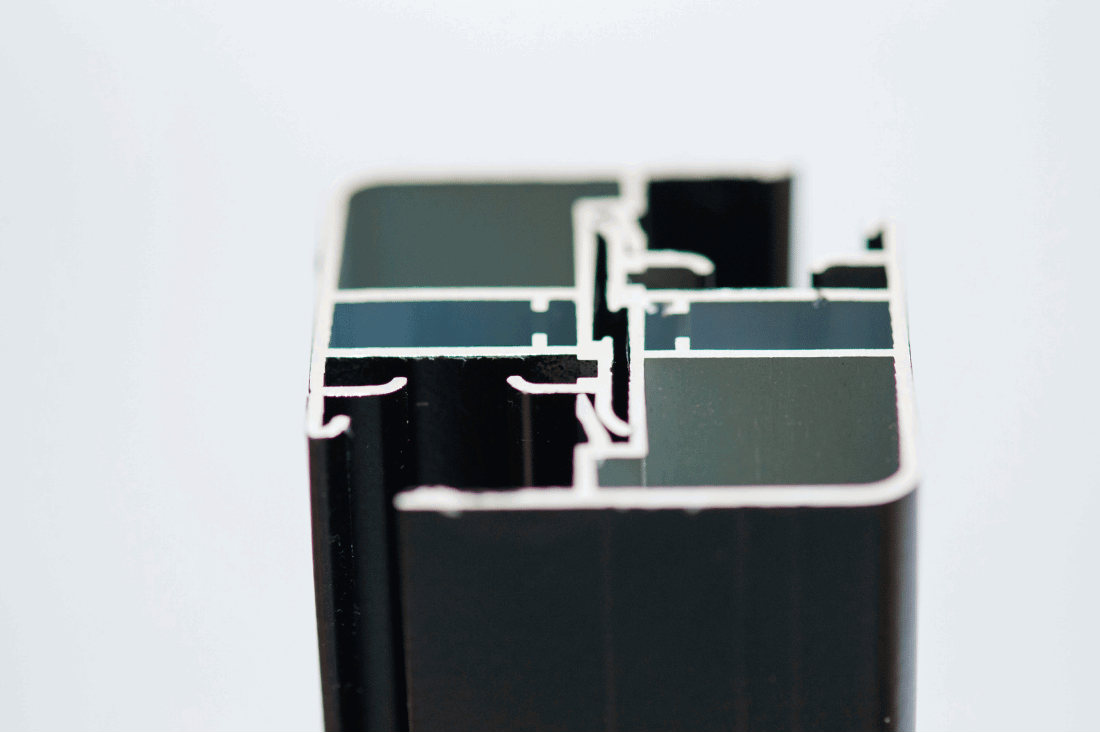

Aluminum profiles are preferred in many sectors thanks to their advantages such as durability, lightness and aesthetics. However, surface treatments are of great importance to further improve these properties of aluminum and make it suitable for various applications. Anodizing (anodic oxidation) and painting techniques are widely used methods to protect the surfaces of aluminum profiles, increase their durability and provide aesthetic appearance.

Anodizing and painting techniques are the most effective methods to improve the aesthetic and functional properties of aluminum profiles. Both techniques offer customizable solutions for various applications while enhancing the natural advantages of aluminum. Kenan Metal is ready to make your projects more durable and aesthetic with its expertise in surface treatments.

With the high-quality anodizing and painting techniques offered by Kenan Metal, you can achieve both long-lasting and visually striking solutions in your projects. You can trust Kenan Metal for aluminum profile solutions suitable for your needs!

Anodizing Process (Anodic Oxidation)

What is the Anodizing Process?

Anodizing is an electro-chemical process applied to create a protective oxide layer on the surface of aluminum profiles. This layer accelerates the natural oxidation process of aluminum, making the surface more durable, corrosion resistant and decorative. The anodizing process provides a great advantage for aluminum profiles, especially those used in outdoor applications, architectural projects and industrial areas.

Advantages of Anodizing

- Corrosion Resistance: The anodized layer protects the surface of aluminum against oxidation and environmental influences.

- Aesthetic Appearance: Provides an aesthetic contribution to projects by offering different color and gloss options.

- Surface Durability: Resistance to mechanical abrasion is increased, which extends the life of the products.

- Environmentally Friendly: Anodizing is a coating method that does not harm the environment.

Usage Areas of Anodizing Process

Anodizing is particularly popular in architectural projects (facade cladding, window profiles), electronic equipment and the automotive industry. This process combines both decorative and functional features.

Kenan Metal stands out in the sector with its aluminum profiles processed to high standards, offering all the advantages of anodizing. The company's anodizing technology offers customers durable and aesthetic solutions.

Painting Techniques

Painting of Aluminum Profiles

Painting is a surface treatment applied to aluminum profiles to give them color and protection. Generally, powder coating (electrostatic paint) and liquid painting techniques are used. The painting process provides the possibility to customize the appearance of aluminum profiles in both indoor and outdoor applications.

Powder Painting

Powder coating is applied electrostatically to the surface of aluminum profiles and baked. This technique offers great advantages in terms of durability and color variety.

- Advantages

- High resistance to scratching and abrasion.

- Resistance to UV rays, which prevents color fading.

- Wide choice of colors and different surface textures (matt, glossy, metallic).

Liquid Dyeing

Liquid painting is a coating process by applying liquid paint to the aluminum surface. It provides a thinner coating and is often preferred for special decorative projects.

- Advantages

- Can be applied to fine details and complex surfaces.

- It offers high aesthetic results.

Usage Areas of Painting Techniques

Painting techniques are widely used especially in interior decoration, furniture production, lighting systems and the automotive industry. Coatings with high UV resistance are preferred for outdoor applications.

Kenan Metal adds value to projects in terms of both aesthetics and durability by offering customized painting options according to the needs of its customers. The company applies high quality powder and liquid painting techniques in accordance with international standards.

Comparison of Anodizing and Painting Techniques

| Criteria | Anodizing | Painting |

|---|---|---|

| Protection | High corrosion resistance | Scratch and UV resistant |

| Aesthetics | Natural metallic look | Wide range of colors and textures |

| Thickness | Thin oxide layer | Thicker and more durable coating |

| Area of Use | Outdoor, architectural projects | Interior and exterior applications |

These two techniques can also be used in combination, depending on the needs of the project. The anodized coating provides basic protection, while the painting process gives a decorative appearance.