How Aluminum Profiles Enhance Safety and Performance?

Discover how aluminum profiles enhance safety and performance. Learn about durability, fire resistance, corrosion protection, and sustainable design.

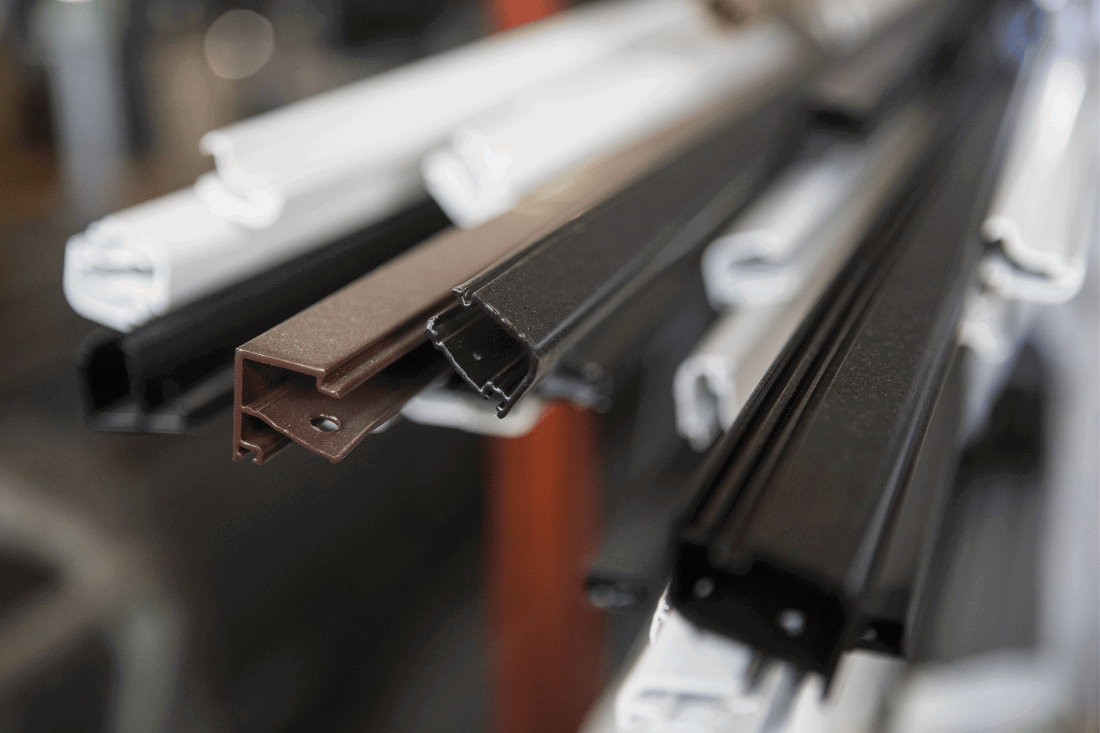

Aluminum profiles play a vital role in modern construction, offering a unique balance of strength, durability, and versatility that other materials often cannot match. From high-rise façades to precision-engineered structural elements, they contribute directly to safer buildings and better-performing projects. Their lightweight yet robust nature ensures efficiency during installation while meeting strict safety requirements in demanding environments.

In today’s construction industry, safety and performance are inseparable goals. Developers, architects, and engineers increasingly turn to aluminum solutions because they provide both functional reliability and design flexibility. With proper extrusion, finishing, and certification, aluminum profiles become not just a building material but a guarantee of long-term stability and efficiency.

Read This: Aluminum Profile Types and Usage Areas

Key Ways Aluminum Profiles Support Safe and Efficient Construction

Aluminum profiles excel because they are engineered to perform under pressure—literally and figuratively. Whether it’s coping with seismic activity, resisting corrosion, or reducing the carbon footprint of a project, profiles deliver measurable benefits. Below are the most important factors that demonstrate their impact.

1. Structural Safety and Seismic Resistance

The high strength-to-weight ratio of aluminum profiles allows them to withstand wind loads and seismic forces without adding unnecessary mass to a building. Lighter structures reduce overall stress on foundations and enhance resilience against earthquakes, a key requirement in modern safety codes.

2. Fire Resistance and Environmental Protection

Through surface treatments such as anodizing and QUALICOAT-certified powder coating, aluminum profiles gain improved fire resistance and weatherproofing properties. These treatments provide an extra layer of safety by preventing structural degradation in humid, hot, or fire-risk environments.

3. Corrosion Resistance and Long-Term Durability

Unlike steel, aluminum does not rust. Its natural oxide layer and advanced coatings ensure that profiles remain strong and stable even after decades of exposure to outdoor conditions. This reduces maintenance needs, increases lifecycle performance, and secures the safety of building occupants.

4. Lightweight Design for Easier Handling and Faster Projects

Being about one-third the weight of steel, aluminum profiles simplify transportation and installation. This not only accelerates construction timelines but also reduces the risk of accidents during handling, enhancing on-site safety.

5. Design Versatility and Custom Applications

Aluminum extrusion technology enables the creation of highly customized profiles with precise geometries. From curtain walls and window frames to specialized industrial parts, this adaptability ensures that safety and performance go hand in hand with architectural creativity.

6. Sustainability and Eco-Friendliness

Aluminum is 100% recyclable without losing its properties, and producing recycled aluminum requires only a fraction of the energy used to produce primary metal. This aligns with global sustainability goals and enhances the environmental credentials of projects.

7. Applications Across Construction Elements

- Framing & Curtain Walls: Durable yet elegant structures that resist weather and provide transparency.

- Railings & Balustrades: Lightweight and corrosion-resistant, especially in coastal environments.

- Profiles for Doors and Louvers: Provide strength, security, and climatic control with design versatility.

Kenan Metal’s Expertise in Aluminum Profiles

At Kenan Metal, we transform these advantages into actionable solutions for your projects. Here’s why we stand out:

- Advanced Extrusion & Production: Our modern facility produces over 36,000 tons of tailored aluminum profiles annually, with robust surface treatments (QUALICOAT-certified coating and mechanical processing).

- Quality & Compliance: We hold certifications like TSE, IATF 16949, ISO 9001, ISO 14001, ISO 10002, and OHSAS 18001—ensuring both product integrity and environmental responsibility.

- End-to-End Capabilities: From standard profiles to custom designs, we offer a full suite of extrusion, coating, machining, and R&D services to meet project needs.

- Global Reach: Our export-driven production serves markets worldwide with reliability and innovation.

| Benefit | Description |

|---|---|

| Structural Safety | Meets seismic and wind standards; reduces building load |

| Fire & Water Resistance | Enhanced by anodizing and coating technologies |

| Corrosion and Durability | Long-term performance with minimal maintenance |

| Lightweight & Efficient | Easier handling and cost-effective installation |

| Design Flexibility | Supports bespoke architectural solutions |

| Sustainability | Eco-friendly and energy-efficient material |

Aluminum profiles are a cornerstone of modern construction, offering unmatched safety, performance, and sustainability. As a producer with deep expertise and cutting-edge capabilities, Kenan Metal is uniquely equipped to deliver high-quality solutions aligned with these industry standards.

Let us help you elevate your next project with aluminum profiles that excel in safety, innovation, and design.

Read This: Why High-Quality Aluminum Profiles Matter