Turkiye's Leader Aluminum Profile Manufacturer

Aluminum Profile Production

Turkiye's Leader Aluminum Profile Manufacturer

In accordance with changing and increasing demands, from its foundation to the present day, it has quickly incorporated innovative production technologies in its field with the work of expert R&D and P&D staff and it has taken care to meet the customer expectations by reflecting the developments in its products.

Kenan Metal manufactures 1500 TONS (5 INCHES), 1800 TONS (7 INCHES), 2400 TONS (8 INCHES) and 4000 TONS (10 INCHES) with 4 extrusion press machines in a modern production facility designed and built specifically for the production of aluminum profiles. It has achieved an annual production capacity of 36,000 tons with its quality, which has been certified by TSE, IATF, ISO 9001, ISO 14001, ISO 10002 and OHSAS 18001.

QUALICOAT has certified 1 Mechanical Processing Center with an annual capacity of 5,000 tons and 2 Dyeing plants with an annual production capacity of 20,000 tons.

Aluminum Profile Production

Our Mission

Our company, which closely follows technological developments from an innovative point of view and increases its production capacity every day; meets all kinds of demands of stakeholders with its experience and accumulation and leads the sector with its wide product range without borders and main goal of our company, is to achieve permanent superiority in the international markets.

Aluminum Profile Production

Our Vision

As Kenan Metal, we have been active in the design, development and production of special shaped aluminum extrusion profiles for more than 20 years.

Kenan Metal Corporate Film

For over 20 years, Kenan Metal has been shaping the future of aluminum with innovation, quality, and sustainability. From extrusion to surface finishing, we combine technology and expertise to deliver solutions that meet global standards. Every profile we create reflects our commitment to excellence and the trust we build with our partners worldwide.

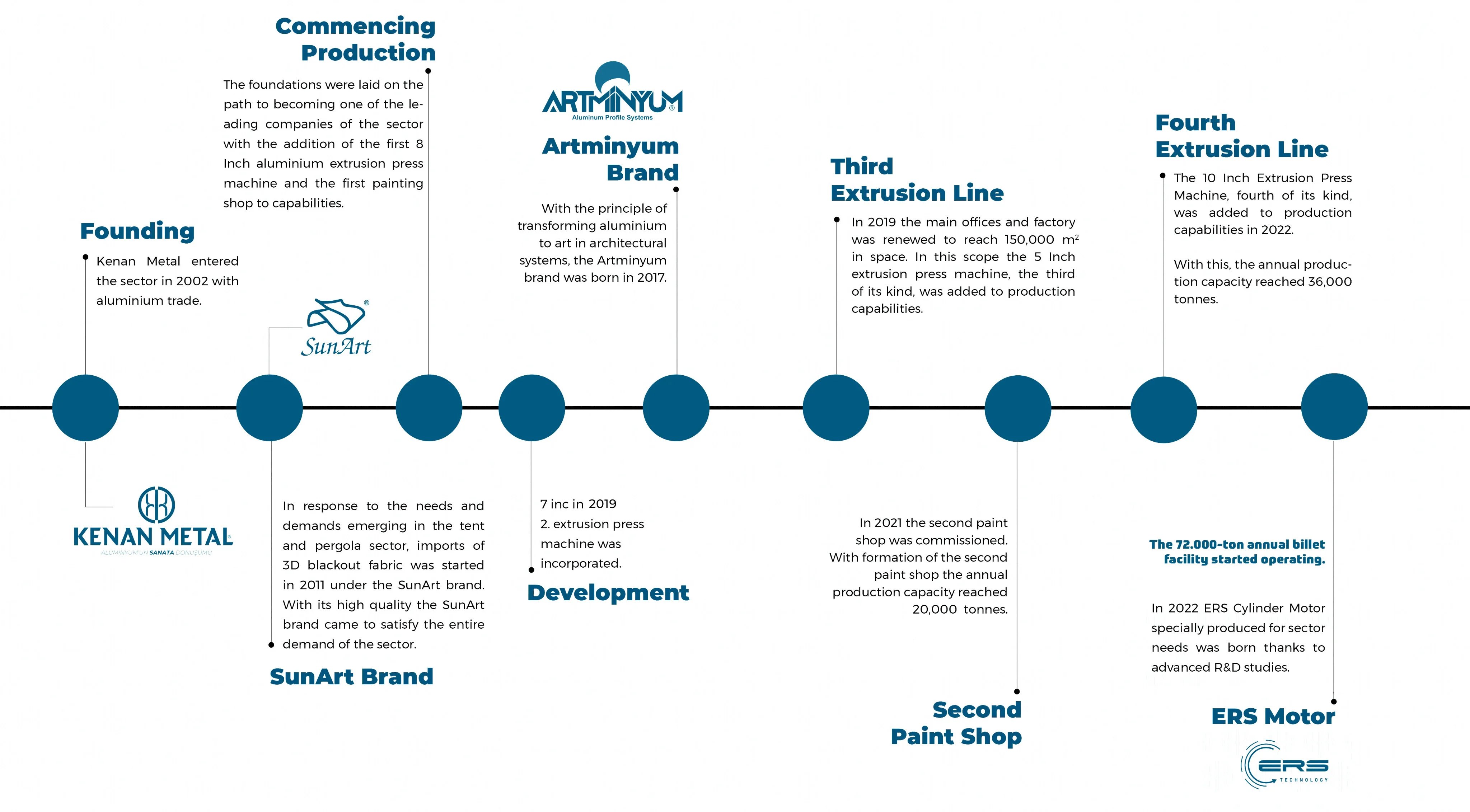

Since its foundation, Kenan Metal has combined decades of experience with a strong culture of innovation to meet the ever-changing demands of the aluminum industry. By continuously investing in R&D and P&D, the company integrates the latest production technologies into its processes and reflects these developments in its products, ensuring high performance and customer satisfaction.

Production Facilities and Extrusion Capacity

Kenan Metal operates with four modern extrusion presses of 1,500 tons (5 inches), 1,800 tons (7 inches), 2,400 tons (8 inches), and 4,000 tons (10 inches). These presses are installed in a state-of-the-art production facility specifically designed for the manufacturing of aluminum profiles. With this advanced infrastructure, the company has reached an annual production capacity of 36,000 tons, positioning itself as a reliable supplier for both architectural and industrial applications.

Surface Treatment and Mechanical Processing

To ensure long-lasting performance and aesthetic versatility, Kenan Metal operates:

- Two powder coating plants with an annual production capacity of 20,000 tons, certified by QUALICOAT.

- One Mechanical Processing Center with an annual capacity of 5,000 tons, capable of producing customized solutions to meet the technical needs of diverse industries.

These facilities enable the company to provide high-quality surface finishes, precise machining, and design flexibility for projects ranging from façade systems to industrial components.

Quality and International Standards

Kenan Metal’s commitment to excellence is supported by internationally recognized certifications:

- TSE (Turkish Standards Institution)

- IATF 16949 Automotive Quality Management System

- ISO 9001 Quality Management System

- ISO 14001 Environmental Management System

- ISO 10002 Customer Satisfaction Management System

- OHSAS 18001 Occupational Health and Safety

These certifications demonstrate compliance with the strictest global standards in quality, sustainability, and workplace safety.

Markets and Industries Served

Kenan Metal exports aluminum profiles to multiple markets worldwide, supporting industries such as:

- Construction and architecture (façade systems, doors, windows, shading solutions, pergolas, winter gardens, and windbreaks)

- Automotive and transportation (lightweight and durable structural parts)

- Electrical and energy (high-performance components for energy efficiency)

- Industrial applications (machinery, equipment housings, and precision systems)

With its integrated production model, Kenan Metal offers not only standard profile solutions but also tailor-made aluminum systems designed in collaboration with clients.

Sustainability and Responsibility

Environmental responsibility is at the heart of Kenan Metal’s production philosophy. By adopting energy-efficient technologies and implementing international standards, the company minimizes its carbon footprint and promotes the use of recyclable materials. Its commitment to green production ensures compliance with REACH and RoHS regulations, safeguarding both people and the environment.

Trusted Partner in Aluminum Profiles

With advanced facilities, certified processes, and customer-oriented innovation, Kenan Metal continues to strengthen its position as a leading aluminum profile manufacturer in Turkey and beyond. The company’s vision is to combine high-capacity production with sustainable practices, providing long-term value for global partners across multiple industries.